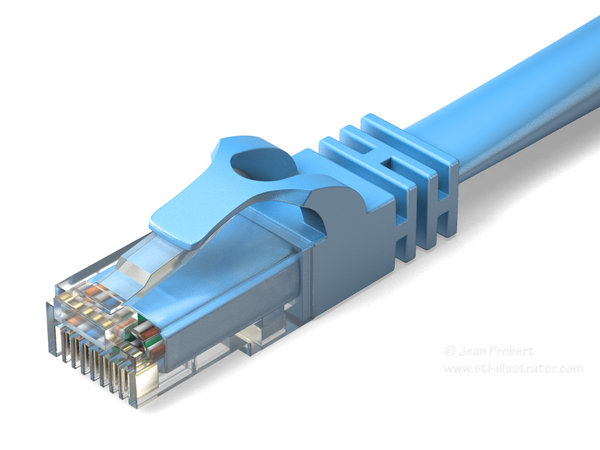

The Uses Of 7 Types Of Telecom Network Connectors

An ideal connector is designed to be resistant to pressure, oil, water and vibration. Other desirable qualities include low cost, compact size, durability, simple tools and high insulation value. The connectors are widely used in communications applications, computers, industrial machinery and consumer electronics. Connectors are classified by the pin spacing in mm (pitch), pin count, and the number of rows.

The information has been shared on behalf of Global Connector Technology , is a leading supplier of standard and custom interconnect products.