How Does A 3D Printer Work?

The 3D printer has come a long way since the mid-eighties when Chuck Hill first invented and patented what is also referred to as stereolithography. It has completely revolutionized the way we produce goods and is now even available to buy for your home.

Various industries have recognized the power of the 3D printer and it is used in everything from the medical industry to the aerospace and aviation industries and the automotive industry. The design and manufacturing process allow users to create complex objects that would be difficult or impossible to make using subtractive manufacturing.

The process of 3D printing is also known as additive manufacturing and refers to the creation of a three-dimensional solid object from a standard CAD (Computer Aided Design) file. In this case, the object is created by adding a chosen material layer by layer. It is a cheaper alternative to forging, molding, and sculpting and allows you to create far more intricate designs.

To make the object, you first need to create a digital blueprint. You can either create your own design using CAD or animation modeling software, or you can purchase ready-made designs online. You can also employ someone to create a unique design for you if you require something a little more specific.

Your plan is divided up into digital cross-sections by the software, which allows the printer to create the object one layer at a time. These cross sections will tell your printer everything it needs to know to make the object, including the exact shape and size it needs to be. Once you have a complete design, you can send it over to the printer with the standard file extension .STL. This stands for Standard Tessellation Language or stereolithography and contains sliced up 3D polygons, which are easy for your printer to read.

When it comes to making the object, different 3D methods can be employed, including selective laser sintering (SLS) and Fused Deposition Modelling (FDM). The most commonly used method is FDM, in which the print material is first melted using a hot glue gun, before being extruded through an active tool head. Materials are typically durable plastics and metals, such as Polycarbonates, ABS plastic, Nylon, and PLA.

The printing material comes through the nozzle of the printer as a filament, essentially a thin wire. The printer then places this material onto the build plate, and the object is created from the bottom up, one later at a time. The design and manufacturing process give you lots of freedom to get creative with your designs.

The worldwide 3D printing industry is huge and expected to grow from $3.07 billion in revenue in 2013 to an impressive $12.8 billion over the course of just five years. The reason it’s such a big industry is that it is used in so many different businesses, particularly for rapid prototyping. It allows companies to improve the way new products are developed and cuts down on time-to-market. Not only does it cut down on time, but it also cuts down on the amount of money you need to spend to produce a prototype.

The medical industry uses it to make implants and prosthetics, while the automotive industry is using it to make functioning parts for use in test vehicles, and the aviation industry is using it to produce engine parts for jets. The versatility in 3D printing has allowed different industries to use the process in a huge variety of ways.

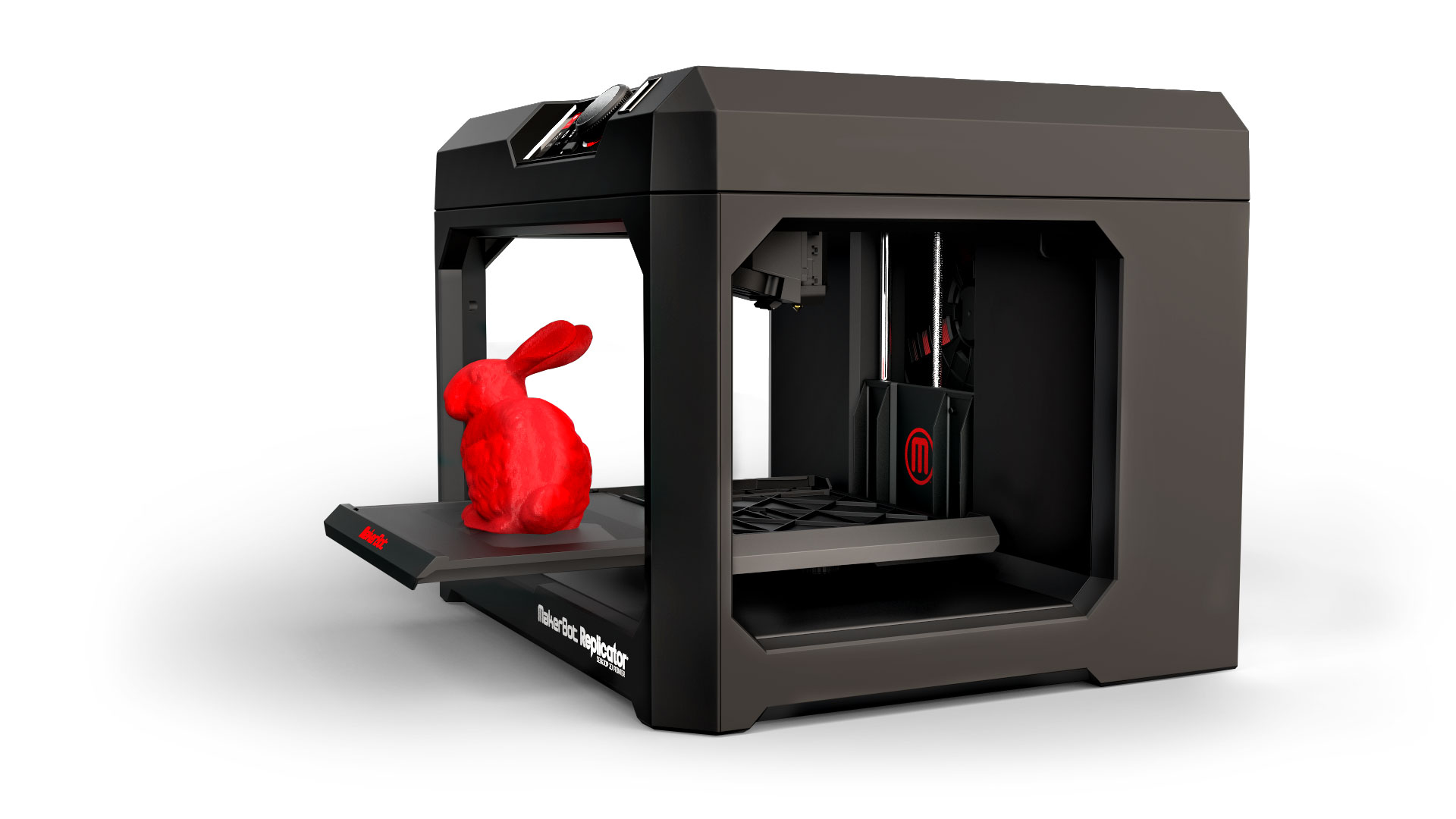

Of course, 3D printing is not just for large businesses. Smaller, consumer-friendly 3D printers have managed to bring additive manufacturing right into people’s homes. Now you can create your very own design and have it printed off in the comfort of your home. The possibilities really are endless, and it is worth taking a look at websites that sell ready-made designs if you are looking for a little inspiration on what to design.

Some interesting and useful objects previously made with 3D printers include AA to C battery adapters, shopping bag handles, plastic hammers, a wall outlet shelf for your smartphone or tablet, an articulated lamp, plastic wrench, self-watering planter, and a survival whistle. These objects give you an idea of the kind of creative and purposeful objects you can create to improve your day-to-day life.