<p style="text-align: justify;"><span style="font-weight: 400;">Are you going to buy stepper motor for your car? Well, your search ends here. There are different kinds of stepper drivers are available to choose. Each driver has unique features and functionality. By reviewing different drivers, you will be able to select the best one for your digital devices. </span></p>

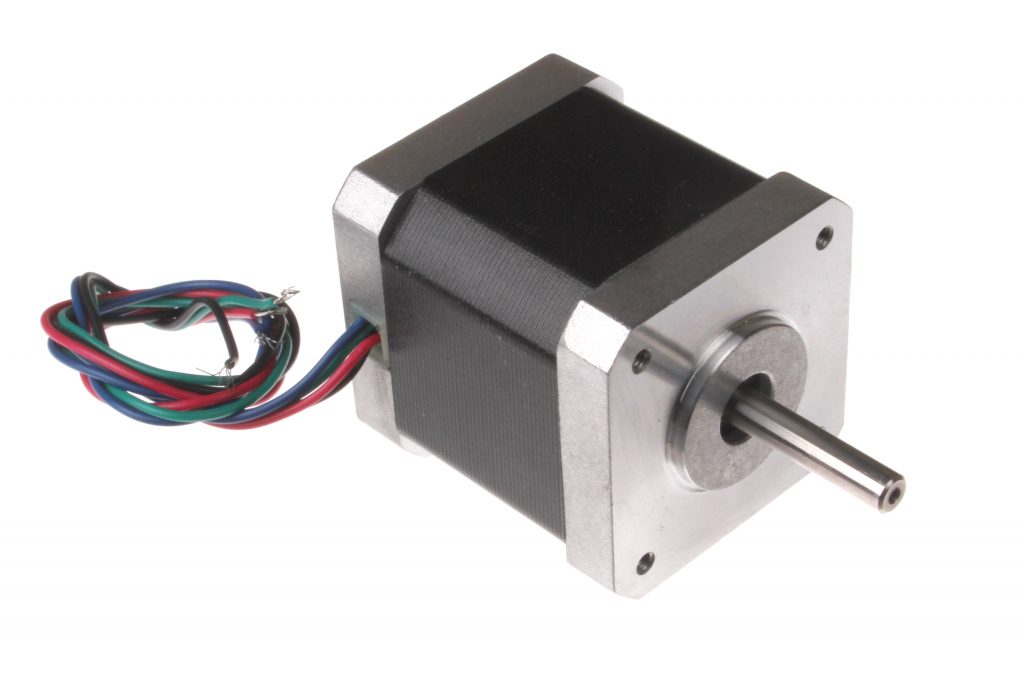

<p style="text-align: justify;"><span style="font-weight: 400;">A stepper motor is an electrically powered motor. When current passes to the stepper drive shaft, it starts to rotate to some extent. However, the stepper motor does turn either smoothly or continually. The stepper motor is specially designed to control the movements of the digital devices. </span></p>

<p style="text-align: justify;"><span style="font-weight: 400;">It is wildly used in many applications such as printers, robotic arms, robotic kits and much more. The necessary forms of the stepper motor are a car, which we use it for daily commutation. It is also known as controllers, which can be categorized into different types based on the input parts. </span></p>

<p style="text-align: justify;"><span style="font-weight: 400;">Before buying a stepper motor, you need to consider some important factors like a coil, stepper design, stepper type, step frequency, number of wires, motor features, etc. It can be categorized based on the name of the coil in the cable. Apart from that, the motor has a significant impact on the shaft. Based on the engine, it can be classified into the unipolar or bipolar driver.</span></p>

<ol style="text-align: justify;">

<li><b> Chopper Drivers</b></li>

</ol>

<p style="text-align: justify;"><span style="font-weight: 400;">There are different types of stepper drivers, of which chopper drivers are the most common type. Depending on the kind of task that a stepper motor supplies, you can choose the best stepper drives. It is also known as a constant current driver, which can supply continuous current to the device. It is equipped with high power resistors, which can enable the user to alter the voltage signals whenever required. When a high voltage is passed to the coil, the current flows stop until coil gets desired current. High-Frequency chopper drivers are used in the primary applications. And, low-frequency drivers will produce unwanted whining or humming sound. </span></p>

<ol style="text-align: justify;" start="2">

<li><b> Unipolar Drivers</b></li>

</ol>

<p style="text-align: justify;"><span style="font-weight: 400;">The unipolar drivers are usually compatible with the essential motors with six wires. In each phase, it incorporates double wrapped coil. In case magnetic polarization occurs, unipolar drivers can quickly reverse the directions of the current.</span></p>

<p style="text-align: justify;"><span style="font-weight: 400;">Compared to the bipolar drivers, it is less expensive, easy to use and maintain. As it encompasses few features, it is inefficient in some cases. Because it converts a lot of input energy into heat, it wastes substantial current flows. However, it is easy to set up the unipolar devices. </span></p>

<ol style="text-align: justify;" start="3">

<li><b> Bipolar Drivers</b></li>

</ol>

<p style="text-align: justify;"><span style="font-weight: 400;">The bipolar devices are compatible with six, four and eight-wire stepper motors. It can be used with two-phase stepper motors. As it has only one wound coils, current direction can be quickly reversed to avoid further magnetic polarization. Unlike unipolar devices, the </span>bipolar stepper motor<span style="font-weight: 400;"> </span><span style="font-weight: 400;">can be very useful. It produces 40% more torque than the unipolar devices.</span></p>

<ol style="text-align: justify;" start="4">

<li><b> Resistance Drivers</b></li>

</ol>

<p style="text-align: justify;"><span style="font-weight: 400;">The resistance and inductance drives are commonly termed as L/R drives. It comes under the category of constant voltage drives like Chopper drives. Unlike Bipolar devices, it is less expensive but more efficient. It makes use of the induction circuit to control and resist the current flow.</span></p>

<p style="text-align: justify;"><span style="font-weight: 400;"> Resistance drives are equipped with induction circuit. Reaching the full torque can be time-consuming. Moreover, it wastes a lot of input energy. However, the unwanted input energy gets converted into heat.</span></p>

<ol style="text-align: justify;" start="5">

<li><b> Bi-Level Drivers</b></li>

</ol>

<p style="text-align: justify;"><span style="font-weight: 400;">Unlike other drivers, Bi-level drivers are very efficient and easy to manage. It reduces the risk of overheating as it loses very little energy. The operating principles of the bi-level driver are much like the chopper one. The high voltage current is allowed to pass through the coil rapidly. </span></p>

<p style="text-align: justify;"><img class="aligncenter" src="https://c2.staticflickr.com/4/3028/2280815917_d5ca96e615_z.jpg?zz=1" alt="5 Types of Stepper Drivers You Must Know" width="500" height="397" /></p>

<p style="text-align: justify;"><span style="font-weight: 400;">Once it attains the desired phase, the high voltage current is replaced by the low voltage current to minimize the heat and energy loss. However, it is not compatible with the motors that use micro stepping techniques. </span></p>

<p style="text-align: justify;"><span style="font-weight: 400;">The step modes are responsible for size, speed, and performance of the driver shaft. The </span><a href="https://www.omc-stepperonline.com/stepper-motor-linear-actuator"><b>stepper motor linear actuator</b></a><span style="font-weight: 400;"> has </span><span style="font-weight: 400;">step modes, which are categorized into wave step modes, full step modes, half step modes and full step modes.</span></p>

<p style="text-align: justify;"><span style="font-weight: 400;">When it comes to buying the stepper drive, the budget is the most significant challenge. Before choosing the right one, you need to make sure that the drives are compatible with the motors. If you decide bi-level drives, it won&#8217;t work for the devices that perform micro stepping.</span></p>

<p style="text-align: justify;"><span style="font-weight: 400;"> The bi-level </span>stepper driver<span style="font-weight: 400;"> is stable and guarantees smooth performance. If you have a very tight budget, then second-hand stepper motors will be your first option. However, it is good to get a fresh motor and mechanical parts to avoid the loss of extra input energy.</span></p>

5 Types of Stepper Drivers You Must Know